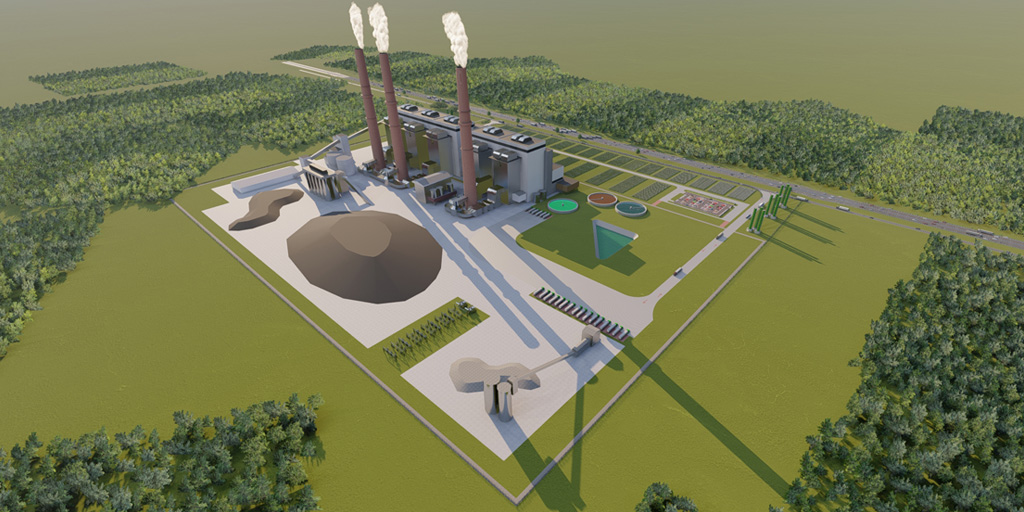

COGENERATION POWER PLANT

Our offer focuses on delivering advanced solutions in the field of cogeneration and trigeneration, designed to optimize the use of available energy resources with minimal environmental impact. By employing environmentally friendly production methods such as biofuel-powered internal combustion engines, biogas-fired gas turbines, or innovative fuel cells, our systems can efficiently convert local biomass sources and organic waste into clean energy.

Furthermore, with an eye toward the future, our systems are equipped with ecological enhancements such as absorptive and adsorptive chillers, which utilize waste heat to produce cooling, and integration with advanced HVAC systems, allowing for even better utilization of generated energy and further optimization of buildings’ carbon footprint.

We offer solutions that not only enhance energy efficiency but also contribute to a more sustainable development, opening new possibilities for industry, local communities, and urban infrastructure. Our cogeneration and trigeneration offer is more than just energy – it’s the future of sustainable and efficient resource utilization.

Cogeneration and trigeneration are processes that increase energy efficiency by simultaneously generating electricity and heat, and in the case of trigeneration, cooling as well, from a single energy source. To better understand their environmental impact, we can categorize the energy production methods used in these processes into more and less eco-friendly ones.

Eco-friendly Production Methods

Biofuel Internal Combustion Engines:

- Internal combustion engines can be powered by biofuels, reducing greenhouse gas emissions compared to traditional fossil fuels.

- Mainly used in smaller installations, such as local industrial plants or public buildings, where they can efficiently utilize local biomass sources.

Biogas Gas Turbines:

- In larger installations like cogeneration plants, gas turbines can be powered by biogas, a renewable energy source.

- This allows for the reduction of the plant’s carbon footprint and the utilization of organic waste.

Fuel Cells:

- Fuel cells convert the chemical energy of fuels, such as hydrogen, directly into electricity, water, and heat, with minimal emission of harmful substances.

- They can be used in trigeneration energy cascade systems, where their high efficiency contributes to the overall performance improvement of the system.

Less Eco-friendly Production Methods

Traditional Internal Combustion Engines:

- Internal combustion engines that use fossil fuels generate higher greenhouse gas emissions and other pollutants.

- Despite their efficiency in cogeneration, their environmental impact remains significant.

Fossil Fuel Gas Turbines:

- Similar to internal combustion engines, fossil fuel gas turbines are more efficient than traditional power plants but still emit significant amounts of CO2 and other pollutants.

Steam Turbines:

- Traditional steam turbines often rely on the combustion of fossil fuels, leading to greenhouse gas emissions.

Despite their use in large cogeneration plants, there is a need for more eco-friendly alternatives.

Eco-friendly Improvements

Utilization of Absorption and Adsorption Chillers:

- These use waste heat to produce cooling, which is more eco-friendly than traditional cooling methods, reducing electricity consumption and greenhouse gas emissions.

Integration with HVAC Systems:

- Efficient use of energy generated in the cogeneration/trigeneration process for heating, ventilation, and air conditioning (HVAC) increases the overall energy efficiency of buildings and lowers their carbon footprint.

Cogeneration and trigeneration can significantly contribute to increasing energy efficiency and reducing the carbon footprint, especially when powered by sustainable energy sources. Using eco-friendly methods such as biofuels, biogas, or fuel cells can significantly reduce the negative environmental impact. In contrast, traditional methods, based on fossil fuels, although efficient, require additional innovations to become more environmentally friendly. Integrating advanced technologies, like absorption and adsorption chillers or efficient HVAC systems, in cogeneration and trigeneration installations can further improve their eco-friendliness and efficiency.